Round steel :6-50mm Class of reinforced steel bar :6-40mm Flat steel :80*15mm Angle steel : 63*63mm Square steel :40*40mm Cutting frequency : 28times/min Motor power 4kw

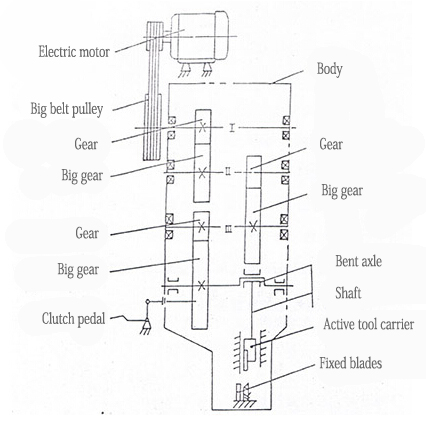

1. GQ50 steel bar cutting adopts enclosed housing, lubricate system, dual-mass flywheel and with clutch structure.

2. It works with high efficiency and safety, which is easy to operate and maintain, light in weight and energy saving.

3. Double mass flywheel, which assure strong enough power for cutting.

Features

1. It is highly structured with reinforced body, small size and reliable quality.

2. It applies the gear splash lubrication system, which is closed case design.

3. If fill enough lubricant oil of 8 or 10kg, it can work continuously for more than three months.

4. Energy saving , because of the improvement of lubrication and the adoption of rolling bearing at the end of gear axis, the resistance is small. Comparing with the other similiar products, our machines can save on third power with the same loading .equipped with rolling wheels, which enables the machine to be moveable .

5. This machine adopts high-rigid knife block and linkage, high-speed machine of national standard. And it has reliable quality and long life.

Model

GQ50

Cutting diameter

Round steel :6-50mm

Class of reinforced steel bar :6-40mm

Flat steel :80*15mm

Angle steel : 63*63mm

Square steel :40*40mm

Cutting frequency : 28times/min

Motor power 4kw

Voltage

380V/50HZ

Dimension

1370*550*880mm

N.W:

500KGS

guide graph when steel bar diameter more than 20mm

|

steel bar diametr(mm) |

6-8 |

9-13 |

14-18 |

19-20 |

20-40 |

|

steel bar number each time |

6 |

5 |

3 |

2 |

1 |

caution: when cutting Low alloy reinforced bar,the reinforced bar's diameter must no beyond 32mm .

First: The preparing work before use

1、 Rotate gears with your hand to ensure the mesh situation is normal.

2、 Check the blades is fastness ,the gap between two blades is 0.2-0.5 mm .

3、 Check every bolt on the machine.

4、 Check electric equipment,ensure the insulativity , equiped electric leakage protection equipment,check the ground electrode connect ground.

5、 Must lubricate each rotated part of the machine.

6、 No-load test,if there some abnormal phemomenon appear,stop it and repair.

Second:Matters attention when using.

1、Reinforce bar must under the blade ,should not use the top part of blade when there is not necessary ,to prevent overload.

2、When working,the blade must complete,and check the fastness of blade,when it is broken,change a new one right away.

3、If some problem appear when it is working,cut off power source immediately and check repair.

4、Any repair or modify work is forbidden when it is working.

5、Shield must be covered on the machine before running to prevent accident take place.

6、When you tread clutch pedal you must tread it correctly otherwise it will reduce the service life if you usually tread the pedal uncorrectly .

7、When it is cutting, clear the scrap at any time,to prevent the damage of fastness bolt that caused by extrusion.

1、Clear scrap under blade and near blade with brush.

2、When working,pay attention to the running situation, check the overheating situation of bearing bush.

3、When it work for the first time ,you have to fill gear oil(150-220# gear oil 8 - 10 kilogram in the machine cavity) before, change gear oil one month later.

|

Itme |

Name |

material |

number |

installation site |

|

1 |

fixed blade |

cutlery steel |

1 |

fastness |

|

2 |

movable blade |

cutlery steel |

1 |

movable base |

|

3 |

bearing bush |

powder metallurgy |

1 |

bent shaft right end |

|

4 |

bearing bush |

powder metallurgy |

1 |

bent shaft left end |

|

5 |

copper bush |

ZQSn6 |

1 pair |

bent shaft connect rod |

|

6 |

base plate |

phenolic cloth laminate |

1 |

side shield |

In order to prolong service life of the equipment and reduce the cost, please read the instruction manual carefully before operation and maintain the equipment according to signs. Change the OEM gear oil after the first use of 500 hours, then add the same grade gear oil.

[wolwa]

Add:No.8 Shanbo Road, National High-tech Industrial Development Zone,Jining

City,Shandong Province,China

Tel:+86-537-6588123

E-mail:trade@wolwa.cn

mobile 2-dimensional-code

Copyright Right © 2014 www.wolwa.cn Powered By Shandong Wolwa Industrial

Limited Company 鲁ICP备10206551号-6

Copyright Right © 2014 www.wolwa.cn Powered By Shandong Wolwa Industrial

Limited Company 鲁ICP备10206551号-6